Applications

Takahashi Syoten

Installed device

DEPAK thawing machine(SE-SC)

Problems

- Improving the yield

- Maintaining the quality after thawing

- Simplify the thawing procedure

Reason for Installation

In order to reduce losses of food and time

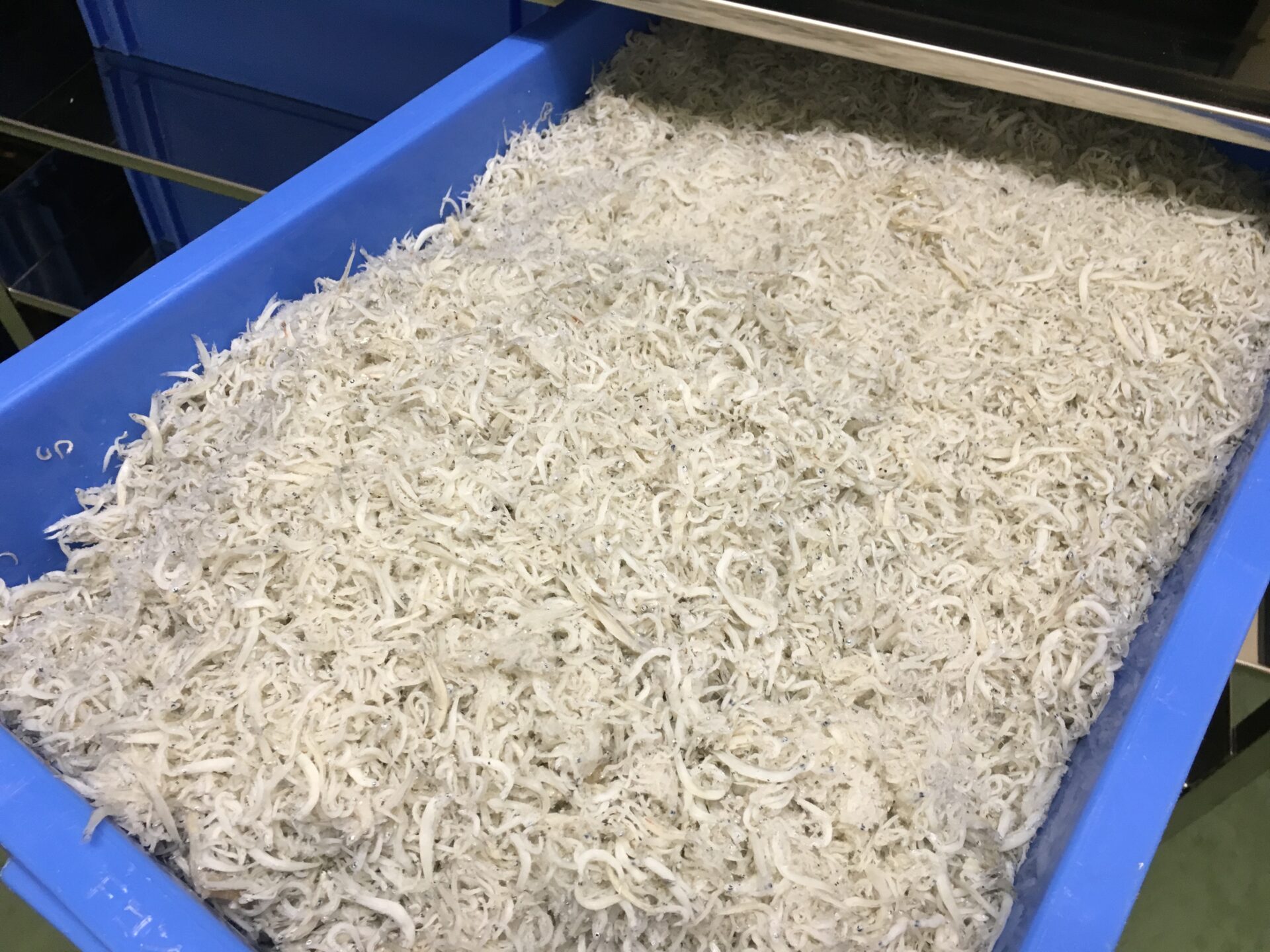

We used to thaw whitebait at 0 degree Celsius in a refrigerator. I think it was not a bad environment for thawing, but the quality was not stable throughout a year. As a result, we had a yield loss of 10-15%.

Because whitebait is especially sensitive to dryness, loss caused by drying out during thawing was also a problem.

It took a lot of time to thaw it, and the thawing time was also unstable. These were stressful for us. Depending on the season, it sometimes took more than 24 hours to thaw it.

Because we wanted to save both food and time, we started to consider installing a thawing machine. Then we saw Santetsu at an exhibition.

Surprising quality of the pre-test

We heard a demonstration would be available before installation, so we asked to test it out thawing whitebait. Because the quality after thawing was better than expected, we decided to install it.

The dryness during the thawing was also suppressed.

We were thinking of applying for a subsidy, but the quality was so amazing that we would have definitely purchase it even if we were not approved for the subsidy.

Effects

After installation, we don’t feel any stress during the thawing procedure.

The quality has dramatically improved, and work efficiency has also improved because of the shortened thawing hours.

We also aimed to create a work environment where our employees can work for many years, and DEPAK contributes to that environment.

We think many companies have some trouble with thawing, and want to recommend the thawing machine to everyone.