Applications

Umenohana co.

Installed device

DEPAK thawing machine (H1000)

Problems

- Improved work efficiency

- Improved quality and yield

Background

Considered using to improve thawing process

When we didn’t have a thawing machine, we pre-thawed in a -8°C freezer and then stored ingredients in the refrigerator until they were needed.

We had to spend a lot of time and effort thawing the meat, since we had to move it while monitoring its condition: if it was not thawed on the inside, we had to temporarily leave it at room temperature. On the other hand, if it was too thawed, we had to temper it in the freezer.

So, when we consulted with our supplier about this problem when we were purchasing a new slicer, we were introduced to Santetsu’s thawing machine. This led us to begin using the thawing machine.

Other manufacturers of various kitchen equipment and machines evaluated DEPAK’s thawing quality and the fact that DEPAK’s quality was recognized by professionals in the field were the most decisive factors in our decision to install DEPAK.

Effects

Successfully improved work efficiency

Before the introduction of the DEPAK thawing machine, we had to move the food many times to thaw it, which took a lot of time and effort. With the DEPAK thawing machine, however, work efficiency has improved considerably, since the food can be thawed at the touch of a button after it is placed in the machine.

It also works well with the slicing machine, which is the next step in the process.

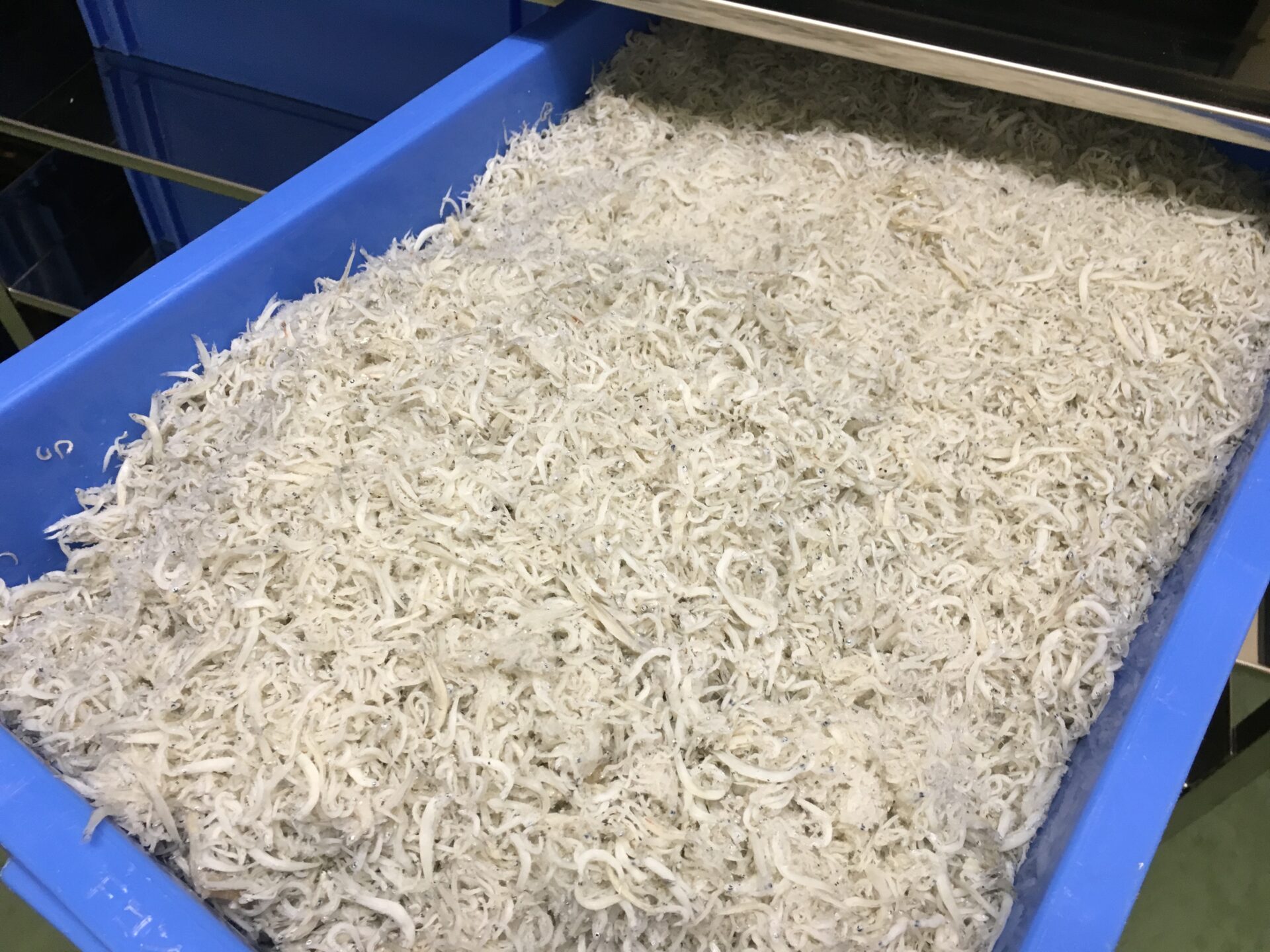

No drip loss and reduced need to clean

Before we started using DEPAK, it took a long time to clean up because of the drip loss when slicing the meat. Since beginning to thaw with DEPAK, there are hardly any drip loss or meat scraps, so the worksite is spotless, clean and hygienic. After slicing for more than 6 hours (about 60 kg in terms of food quantity), there are hardly any scraps. (Left image)

We were able to reduce cleaning time, which led to a reduction in labor required in the slicing department.

Satisfied with thawing quality

We have noticed less drip loss and at the same time the quality has improved considerably. The meat is now bright red in color compared to before, and there have been no complaints from stores, even though the meat is packaged and refrozen after slicing.

It used to take a long time to pack slices of meat because the slices would curl and need to be flattened before packing. However, since using DEPAK, the need for this has been eliminated, leading to time savings.

Through using DEPAK, we have come to realize that preventing drip loss means keeping umami flavor.

Who would you recommend DEPAK to?

Some machines can not only thaw, but also preserve freshness and ripen, so they are good not only for meat processing, but also for restaurants that serve steaks and barbequed meat.

We recommend DEPAK because it can be used in cases where the finished temperature is critical or uniform thawing is required for the next process.

Data

We recommend one of our shops, Kanzaki Ham Factory

At the factory, they use carefully selected pork from Kyushu (Kagoshima and Miyazaki) and authentic German spices and seasonings. The chefs, trained by a German Meister, make fresh and tasty hams and sausages. They use a homemade spice mix with minimal additives, and after aging, they slowly smoke hams and sausages with cherry chips.

They use natural water from 100 meters underground on the property. Please enjoy the taste of Kanzaki Ham Factory’s homemade ham.

神崎ハム工房

〒842-0122

佐賀県神埼市城原3580