Applications

Mizutomi Co.

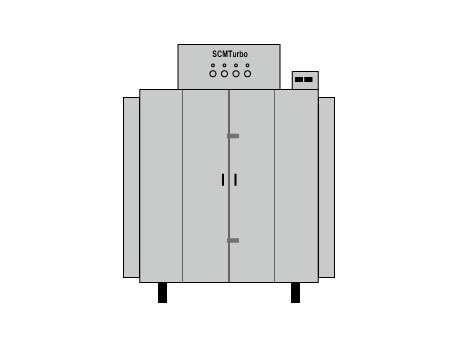

Installed device

thawing machine(SE-SCM Turbo)

Problems

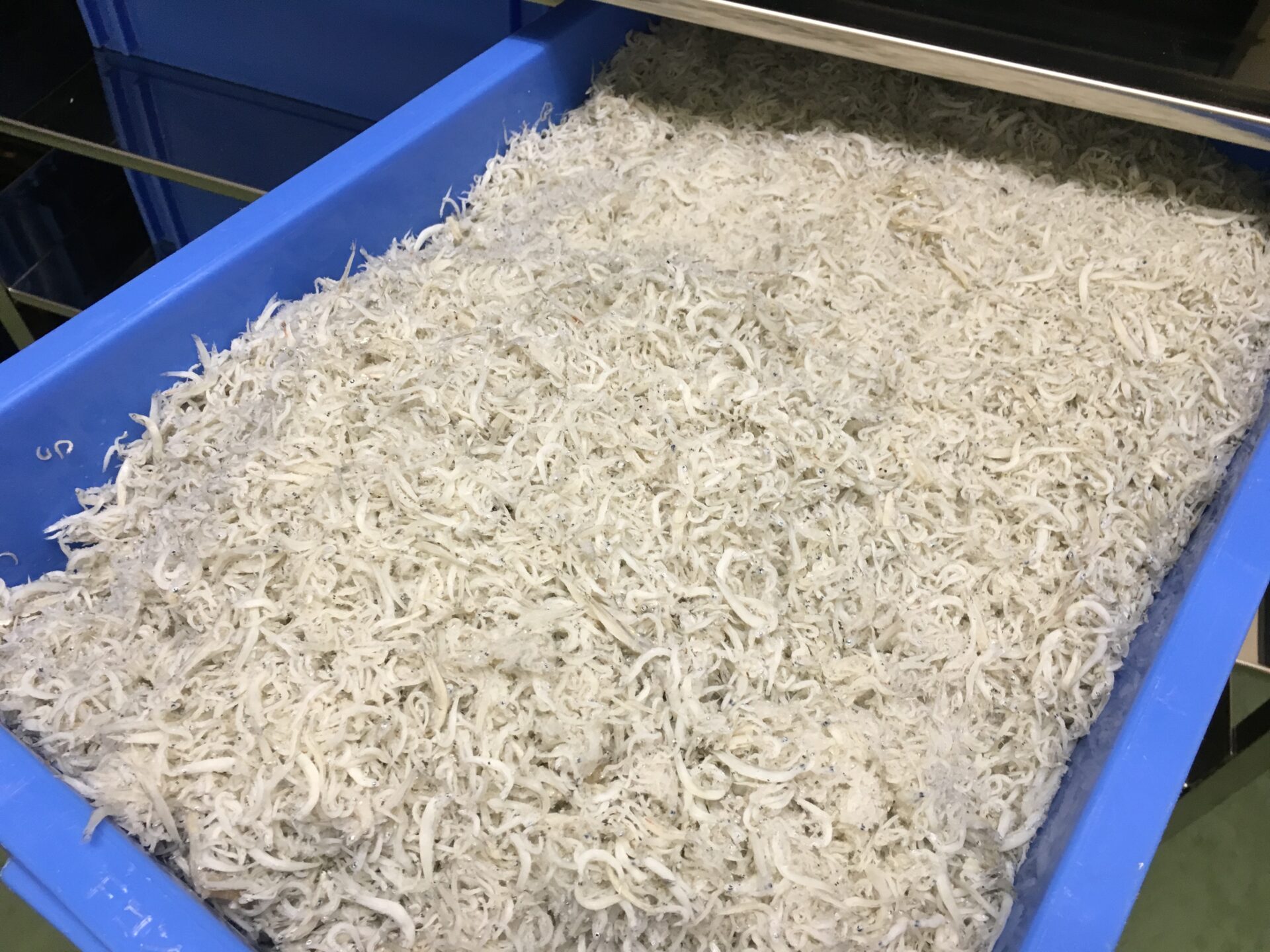

- Improved yield

- Reduced discoloration and drip loss

- Stabiizing of operations

Background

Introduced to improve thawing quality and to stabilize operations

We purchase bulk frozen raw ingredients and separate them out to be thawed every day of the week.

In the past, we thawed them in the refrigerator at a low temperature over a long time, but when the volume was too large or when additional orders came in suddenly, we thawed them under running water.

Of course, we didn’t want to lose quality, but thawing in running water inevitably degrades the quality and leads to increased odor and discoloration. When we were recommended the DEPAK thawing machine, we wondered ‘Is the thawing machine necessary?’

But once we started to use it, the thawing machine is an absolute necessity. It thaws in a set amount of time. We no longer have any variability in work time!

Effects

Improved yield and efficiency

The quality was not only maintained, but also improved with less drip loss.

We have been able to be flexible with sudden additional orders. Since there is no longer any need for thawing under running water, there is no longer any odor, and we feel that this has led to improvement in the sanitary environment of the processing plant.

After thawing, we sometimes transfer the meat to another container and temporarily store it in the refrigerator. Since this SCM Turbo is installed inside the refrigerator, we have greatly reduced the time and effort required to transfer it. And there is no loss of quality, so we can store it safely. We have spare carts for more efficient operation. As soon as the meat in the previous cart finishes thawing, it is replaced with the next cart, allowing the next thawing to begin more smoothly, so it can thaw two or three times a day, leading to increased production volume.

Now, thawing the Wagyu beef which used to be so difficult is no problem!

The only thing more troubling than thawing the chicken was thawing the Wagyu beef. It took a couple days for the Wagyu beef to thaw and be ready for use due to its large size.

We also wanted to improve the quality as the drip loss volume was very large when thawing under running water. The thawing results of the chicken gave us a sense of expectation, but when we thawed the Wagyu beef, the results were even better than we had expected. The thawing time was much shorter than it was previously and thawing process was more stable.

Now, we fully understand how to use SCM Turbo, so we are trying to find other ingredients we could thaw with it.

Now, we feel using this SCM Turbo is nothing but a benefit.

We definitely recommend this thawing machine for those involved in food processing.

Data

We deliver safe, secure, high-quality products from Okinawa, Japan, which is the closest city to the rest of Asia.

Mizutomi Co.

13-43 Shuzaki, Uruma City, Okinawa, Japan