DEPAK Thawing H Series

With the DEPAK thawing machine, we pursue the maximum efficiency of heat exchange of products through our proprietary technology.

DEPAK ensures even and high quality thawing with its technology for controlling the temperature inside the refrigerator and applying air evenly to the ingredients.

Once thawing is complete, it automatically switches to the freshness preservation mode, enabling storage at the optimum temperature for the next process.

Our customers include food processing plants, prepared food processing plants, and restaurants, and we can make proposals for customers according to the type and size of the ingredients.

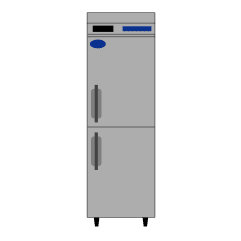

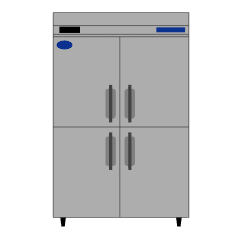

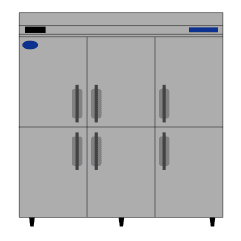

Reach-in type

| Main applications | Restaurants and eating and drinking shops |

|---|---|

| Feature | No installation/ construction required, wide range of products |

| Approximate processing volume | up to 120 kg |

SCM Turbo

| Main applications | Food processing plants |

|---|---|

| Feature |

No construction/ installation work required. It can be installed in existing refrigerators and moved with casters. |

| Approximate throughout | up to 180 kg |

| SE-H500 | SE-H1000 | SE-H1300 | SE-H1600 | SE-SCM Turbo | |

|

|

|

|

|

|

| width(㎜) | 610 | 1200 | 1500 | 1800 | 1270 |

| Height(㎜) | 1890 | 1890 | 1890 | 1890 | 1820 |

| Depth(㎜) | 800 | 800 | 800 | 800 | 1820 |

| Power Supply/Source | Single Phase 100V | Three-phase 200V | Three-phase 200V | Three-phase 200V | Three-phase 200V |

| Download Dimensions |

(68KB) |

(83KB) |

(89KB) |

(77KB) |

(971KB) |

Walk-in type

| Main application | Food processing plants |

|---|---|

| Feature |

Can be retrofitted to existing refrigerators. Can be constructed in accordance with the installation location |

| Approximate processing volume | 100kg~ |

Mainly custom-made. Please refer to the following page for the installation process

Products TopCase Studies

Click here to see what our customers have to say about our products

Go to Case Study Page